London/UK – Miele S8 Silence Plus Allergy model, features an added value Timestrip solution to alleviate the problem of remembering when to change and replace the all important filter.

The S8 unit features the HEPA AirClean filter, a HEPA Class 13 filter which achieves 99.95% filtration and holds back even the most minute particles and pollen, making it an ideal choice for allergy sufferers.

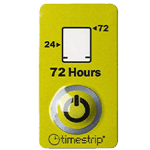

Timestrip change and replace reminder indicators

Miele has chosen Timestrip to provide the change and replace visual reminder on the HEPA filter cartridge, to provide a clear visual notification of the need to replace the filter.

Activating the indicator couldn’t be easier: when fitting a new filter, the user simply presses on a green arrow indicator on the side of the filter housing the Timestrip. This triggers the Timestrip and results in the release of a specially formulated fluid encapsulated into the smart label. As the months pass, red indicator fluid slowly extends across the time check window. After approximately one year, the fluid fills the window and reaches the right-hand end of the strip, prompting the user to replace the saturated filter.

According to Miele: “Miele’s HEPA filters are equipped with a Timestrip indicator – this innovative filter replacement reminder is attached directly to the filter. When the bar is completely red, it indicates that the filter is saturated and must be replaced. The Timestrip helps you to keep a check on your filter and ensure that it is functioning at its best.”.

Commenting on the Miele project, Timestrip’s Nora Murphy said

“This is a great example of a low-cost solution to the age old problem of reminding consumers that components in their products do need changing at the correct interval, and shows how leading brands are choosing Timestrip to help make this a simple, effective and value-adding proposition.”

Timestrip smart indicators were used in a study by academics at Reading School of Pharmacy, part of The University of Reading, into people’s confidence in the quality of medicines.

The study focused on the potential re-use of returned medicines. It found that participants’ intention to take part in medicines re-use increased with the presence of the Timestrip® Plus temperature sensors on the packaging. The perceived social pressure to accept the medication also increased. The effect of the indicators was even greater than the promise of pharmacist visual checking of the medicines.

Although medicines re-use is not at present allowed in the UK, the presence of Timestrip indicators on packaging is understood to be a marker of their quality.

Ref: Lam, Y.; McCrindle, R.; Hui, T.K.L.; Sherratt, S.; Donyai, P. The Effect of Quality Indicators on Beliefs about Medicines Reuse: An Experimental Study. Pharmacy 2021, 9, x. https://doi.org/10.3390/xxxxx. Read more here: https://www.mdpi.com/2226-4787/9/3/128

eTimestrip Smart Indicator with Mobile App for Report Storage

Timestrip®, the developer of smart indicator technology, is launching a completely new range with two electronic temperature indicators. They will be important in monitoring the safe storage and transportation of a wide range of goods including pharmaceuticals, vaccines, healthcare, food produce, adhesives and inks.

Timestrip Complete (‘TC’) indicators are extremely easy to use, highly versatile and can be attached to products at unit, case or pallet level. They track any breach of temperature outside the designated range, helping manufacturers and logistics staff to safeguard product quality and meet regulations.

The new Timestrip range comprises two indicators. The TC489 is an intelligent device that monitors temperature data every minute with high accuracy. The key alert temperatures can be selected as standard e.g. 2-8ºC, or can be specified as bespoke across a wide temperature range as low as -30ºC or as high as 60ºC.

The TC489 has upper and lower limit alarms, and can communicate wirelessly using near field communication (NFC) via a free app, creating a comprehensive data report that includes: number of times limit exceeded, total time limit exceeded and alarm status. Weighing just six grams, it also provides a clear visual signal using built in LEDs.

The TC490 is a simpler device monitoring similar ranges with a 180 day service life, irreversible alarms, and provides a highly cost effective solution to monitoring a wide range of sensitive products.

The new eTimestrip TC products offer our clients solutions for applications that need accurate temperature monitoring, and where strong functionality is needed in most critical applications. They provide clients with the assurance that products have been correctly stored and transported all the way from manufacture to the point of use.

Nora Murphy, Commercial Director of Timestrip.

The new TC range follows the successful introduction last year of Timestrip’s first electronics product, the eTimestrip TIR.

ITV News sent a film crew to interview our Commercial Director, Nora Murphy recently.

Timestrip has responded rapidly to the coronavirus challenges, and Nora was asked about the role of the new products in ensuring that vaccine supplies can move safely through the cold chain.

Timestrip®, the developer of smart indicator technology, has released two new ranges designed to be used with the latest coronavirus vaccines now becoming available. The indicators track temperature and time, and will ensure that vaccines are fresh when administered to patients.

The Timestrip Vaccine Thaw Timer is an event thaw indicator with 24 hour time indication calibrated to run at fridge temperatures. It can be packed with vaccines that require storage at -70°C in the ultra-cold chain, and automatically starts monitoring as the vaccine is thawed and transferred to chilled conditions at the hospital or surgery. It then tracks the time from thaw at 6 hours, 12 hours and up to 24 hours, meeting the specifications for use from manufacturers such as Pfizer.

The Timestrip Vaccine Refrigeration Monitor range comprises three indicators. One is designed to indicate the thawing event of the vaccine; another will time 30 days duration in refrigerator conditions (2°C-8°C), helping the user to manage the vaccine manufacturer’s guidelines for use.

Then, when the vaccine has been taken from the refrigerator and prepared for use, a third indicator monitors how long it has been exposed to temperatures above 8°C, typically at room temperature. The time ‘run out’ for the Vaccine Refrigeration Monitor VOR12 (Vaccine Out of Refrigerator) is up to 12 hours, with shorter times to an alert being seen at higher temperatures.

These Vaccine Refrigeration Monitor products will help overcome challenges in the handling of COVID-19 vaccines up to the point of administering, and are designed to support the manufacturers’ specification for the handling of vaccines such as those from Moderna.

Both indicators provide a clear irreversible indication to healthcare staff that conditions of storage and handling have exceeded acceptable conditions, and that the vaccine consignment cannot be relied upon.

Based on safe chemical technology, both the Vaccine Thaw Timer and Vaccine Refrigeration Monitor range overcome the limitations of batteries used at ultra-low temperatures.

We continue to innovate our patented technology to bring the benefits to important applications such as vaccine distribution, supply and last mile handling. Using these indicators, healthcare professionals worldwide can be supported cost effectively, and guided through soon to be routine practices of handling and managing these vital resources.

Nora Murphy, Commercial Director of Timestrip.

Timestrip has recently added other products to its range in response to coronavirus. These include an indicator to monitor antiviral solutions, and Rapid Diagnostics 15, a 15 minute timer indicator for use with rapid turnaround lateral flow test kits.

From integrating TTIs used in virus specimen shipping, to vaccine reminder bands, Timestrip has solutions for all sectors of the pharmaceutical and healthcare markets.

Timestrip UK Ltd was featured in Pharmaceutical Manufacturing and Packaging Sourcer this month for the line of smart indicators developed for the healthcare industry.

Read the full article below to see how Timestrip indicators are used on everything from biological specimens and pharmaceutical products to the hospital curtains.

We stock electronic temperature indicators with PDF reporting capabilities, along with chemical based time and temperature indicators.

For further reading about our unique time and temperature applications - click here >

Timestrip has a new white paper detailing the importance of preventing virus transmission in light of the novel Coronavirus disease (COVID-19) pandemic.

For more information on how Timestrip UK Ltd is handling the COVID-19 pandemic, please see this post.

As the impact of the COVID-19 coronavirus outbreak is felt by businesses around the world, we wanted to let our contacts, partners and clients know what we are doing at Timestrip UK.

We are deeply concerned about the welfare of our staff, customers, suppliers and distributors, as we work hard to adapt to significant changes at work.

We regard the health and safety of our employees as of the highest importance, and our people are generally working from their home base using electronic communications including video conferencing. We are reducing travel to a minimum. We also suggest that meetings with external parties are held remotely.

While we do not expect this will cause a loss of service level, should you have any concerns, please let us know.

On a positive note, we would like to reassure you that we are working with our customers and distributors around the world to ensure the continued supply of our time and temperature indicators in the future.

Indeed, we are responding to an increased demand, especially for those products that form a part of best practice hygiene procedures.

Stay safe,

Nora Murphy

Head of Commercial Operations

Timestrip UK Ltd

An FDA-approved Irreversible Time and Temperature Indicator that ensures that only viable whole blood supplies are used post-transit

The high tech, low cost alternative to electronic dataloggers

|

A critical issue for medical professionals is ensuring the viability of blood supplies once they leave the highly controlled storage environment, such as a blood bank refrigerator or a hospital blood storage facility. This aspect of the so-called blood cold chain is essential for ensuring that these are kept at the correct temperature right up to the time they are administered by trauma units, ERs, operating theatre staff, air/ ground ambulances, and any other situation requiring blood to be transported from storage units out to patients.

During transit, whole blood needs to be kept within a temperature range of 2°C/36OF to 10°C/50°F. Below this range, there is a risk of freezing with the formation of ice crystals, rendering the blood unusable, while upper temperature breaches create the possibility of blood being affected by an overgrowth of non-specific bacteria, which may have entered the blood unit during collection or component preparation.

Both these situations have serious consequences: the cost implications of a wasted product and/or more seriously, a patient that is put at risk.

To address these issues, Timestrip® has developed its single-use Blood Temp 10 – a high-tech, low cost Irreversible Time & Temperature Indicator that effectively monitors temperature breaches above 10°C/50°F during transit.

No more guesswork

Thanks to its innovative technology, Timestrip® Blood Temp 10 removes this uncertainty by providing clear, unambiguous data as to whether a supply of whole blood is safe to use or be returned to storage.

This is achieved thanks to the smart label’s two indicator windows:

• the first window to indicate if the label has been activated

• the second to indicate if a temperature breach has occurred

Thus, at a glance, medical staff know if a supply of whole blood is not only safe to use post-transit. The smart label also ensures a higher level of quality of the product is delivered by monitoring of temperature throughout transit.

Moreover, thanks to its irreversible feature, once the smart label has reacted to a temperature breach, this cannot be undone. For security reasons, the colour of the label’s indicator window stays permanently changed.

FDA approved … and more

Timestrip® Blood Temp 10 has FDA certification (FDA 510(k) #BK190363) and is manufactured with controls established by a IQC approved quality management system that conforms with ISO 9001:2015 and ISO 13485:2016.

With a temperature accuracy of +/- 0.5°C, this means that the Timestrip® label is designed with reliable and, more importantly, trustworthy technology as assessed by some of the world’s most stringent criteria. Moreover, extra security is assured by every Timestrip® label having its own unique serial number, thus ensuring full traceability.

Checking this list of features brings

further benefits to healthcare providers involved in the transportation of

whole blood by also ticking the box for local and internal regulatory

compliance.

Cost savings

Because Timestrip® Blood Temp 10 ensures that only viable blood supplies are either administered post-transit, or returned to storage, the possibility of precautionary disposal is eliminated. This reduction in waste can have significant cost benefits.

In fact, studies have shown that loss rates without a Timestrip® are around 5%. These are halved with its use. In fact, reducing a loss rate by 9.9% pays for the total investment and a conservative 19.8% reduction doubles the ROI.

The generation of similar positive temperature monitoring outcomes are possible using other products, such as electronic devices. These, however, are far costlier.

Ease of use

Apart from delivering clear, unambiguous data as to whether post-transit a unit of whole blood may be used or returned to storage thanks its innovative indicator windows, the Timestrip® Blood Temp 10 is also remarkably easy to use.

In fact, unlike other whole blood temperature monitoring solutions on the market, Timestrip® Blood Temp 10 is a unique FDA 510(k) medical device that does not require preconditioning. Moreover, it is also CE approved and designed for:

• quick and easy application

• no prior conditioning by blood storage staff

• temperature breach data delivered at a glance by medical field personnel.

Prior to the transit of a unit of whole blood, a simple squeeze of the label’s activation blister is all that is required for temperature monitoring of a unit of whole blood to begin. Then the label just needs to stuck on the unit.

Squeeze, peel and stick – that’s it!

And the end of transit, Timestrip® technology has also been designed for maximum ease of use:

• until activation, the first indicator window is yellow and the second is white

• upon activation, the first indicator window turns green

• if a temperature breach has occurred during transit, the duration of the breach is indicated by the second white indicator window that proportionately fills up with blue dye

Product Specifications

| 10°C/50°F monitoring |

| Irreversible, single use |

| 19mm x 32mm |

| Field activation |

| Visual proof of temperature exposure |

Advantages over electronic dataloggers

Beyond being less expensive, Timestrip® Blood Temp 10 does not involve a datalogger’s complicated and sometimes cumbersome unit return program that is necessary to make it more affordable. The smart label’s single use indicator makes it the ideal fit for simple, straightforward and effective temperature monitoring.

The Timestrip® also is a super convenient shape: small, flat, with no batteries or any other electronic components to them.

For green credentials, the Timestrip® also outstrips traditional dataloggers in terms of carbon footprint, because the latter eventually needs to be either be thrown away or sent back to source to justify the expenditure.

Lastly, the Timestrip® has the potential of generating more accurate safety data. Indeed, because a container of units of whole blood will tend to use just a single datalogger, inevitably the temperature of ambient air within the container is taken into account, potentially generating less than accurate safety data.

With Timestrip® labels however, every single unit has its own temperature indicator. This means that the possibility of rejecting an entire shipment based on a single result is eliminated.

Timestrip will be attending the 29th Regional Congress of the International Society of Blood Transfusion (ISBT) in Basel, Switzerland from 22nd - 26th June 2019

See our blood temp indicators

We will demonstrate our Timestrip® Blood Temp 10 and Timestrip® Blood Temp 6 at the exhibition. We will be at Booth U106, Hall 4.U, please drop by and get a sample of our Blood Temp indicators to take away with you.

Our Blood Temp irreversible blood bag temperature indicators monitor temperature compliance in blood bags. They are especially relevant for monitoring blood temperature during transit from the highly controlled environment of the blood bank to use or store in a different destination, such as a hospital.

ISBT is a society in the field of blood transfusion, transplants, science and medicine. It facilitates knowledge about transfusion medicine to serve the interests of donors and patients.