Printer powder storage

temperature controlled environments

Monitor the temperature of 3D printer powder with Timestrip neo

Contact us for more information

A global technology leader, operating in more than 170 countries, delivers a wide range of innovative and sustainable products.

One product line is 3D printing, where it supplies a range of high-performance industrial units for applications such as printed prosthetics, fashion goods and automotive prototyping.

One product line is 3D printing, where it supplies a range of high-performance industrial units for applications such as printed prosthetics, fashion goods and automotive prototyping.

3D Powder Storage Conditions

The consumable material used in these printers is highly sophisticated, and needs to be stored at specified ambient conditions. In particular, it must not be exposed to freezing, nor to temperatures above 55ºC (131ºF).

A method was required to monitor storage temperatures and to provide a clear notification if they were exceeded.

A method was required to monitor storage temperatures and to provide a clear notification if they were exceeded.

Temperature monitoring of 3D printer powder

Timestrip Temperature Solutions

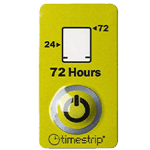

The company turned to Timestrip to provide a solution based on the Timestrip neo electronic indicator that had recently been introduced. Following a short trial, a special custom Timestrip neo was developed to provide constant monitoring of temperature of the 3D printer powder, and to show a clear alert in the event of adverse temperature conditions being met. The indicators are small, very light and can be attached to, or included with, individual products throughout their shipping and warehousing, from the manufacturer right through to the end user.

How Timestrip neo indicators monitor printer powder storage

Activation of the indicators simply involves pressing and holding a button until the green ‘Power on’ LED flashes, and this continues to flash every 30 seconds if no temperature breach has occurred.

Should the temperature drop below 10ºC (50ºF) for more than 20 hours cumulative, a red 10ºC LED will flash. Similarly, should the temperature exceed 55ºC for a similar period, a red 55ºC LED will flash, thus alerting the user with a ‘go / no go’ indication.

After a successful introduction, the company now re-orders supplies as required for use by the customer globally.

Should the temperature drop below 10ºC (50ºF) for more than 20 hours cumulative, a red 10ºC LED will flash. Similarly, should the temperature exceed 55ºC for a similar period, a red 55ºC LED will flash, thus alerting the user with a ‘go / no go’ indication.

After a successful introduction, the company now re-orders supplies as required for use by the customer globally.

Benefits of 3D printer temperature alerts

The company now has a simple, cost-effective monitoring system that fits with their quality control procedures. They can be sure that the 3D printer powder is delivered in perfect condition, or the user alerted if breaches have occurred.

Should there be a doubt about temperature excursions, the Timestrip neo indicators will confirm this, right down to individual product level. This avoids the need to discard whole batches of suspect product. The user has peace of mind knowing that their printer powder has been correctly handled and stored.

Use of indicators such as the Timestrip neo presents the supplier’s brand in the best light, showing due concern for product quality and user satisfaction.

Should there be a doubt about temperature excursions, the Timestrip neo indicators will confirm this, right down to individual product level. This avoids the need to discard whole batches of suspect product. The user has peace of mind knowing that their printer powder has been correctly handled and stored.

Use of indicators such as the Timestrip neo presents the supplier’s brand in the best light, showing due concern for product quality and user satisfaction.