When should you use Timestrip temperature indicators over a datalogger?

Examples of when to use Timestrip temperature indicators

Good Example

pallet / product level monitoring

- Acceptance % = # of temp violated pallets / # of total pallets (example: 25%)

- Waste % = # of non-violated pallets / # of total pallets (example: 75%)

- Large amount of predictive data for decision making

Bad Example

trailer monitoring w/ data logger

- 50% chance of total product rejection

- 100% acceptance or waste rate

- Very little predictive data for decision making

Timestrip solutions are much less expensive than dataloggers.

There is no complicated and cumbersome unit return program necessary to make data loggers more affordable. The low cost of Timestrip makes this single use indicator the perfect fit for a simple, clean and effective temperature monitoring program.

When you like the Environment.

Timestrip Indicators are small, flat, have no batteries or other electronic components to them. They are primarily made of a small amount of polyethylene and less than 1cc of safe, tinted liquids.

Dataloggers are either thrown away, or need to be sent back to source to justify the expenditure, or to get back the information, quite a no no from a carbon footprint standpoint.

When you want to measure as close to the product as possible.

With a datalogger, due to the cost and form factor, they need to be put one per container and somewhere where it can be found, mainly measuring the air temperature in certain location.

Timestrips can be cost effectively placed on or next to the product, and can be used even at case or unit level. No more shipments rejected on the basis of a single result.

Many food safety professionals have attempted to monitor temperature sensitive foods through the implementation of environmental systems designed to take periodic readings of the ambient air temperature. This approach is weak at best because it does not effectively track the actual temperature of perishables at all times. In many cases a change in environmental temperature may have little to no effect upon the actual product temperature and the growth of food borne pathogens.

Product Level data driving a predictable cold chain.

The lack of true product data leads to an unpredictable cold chain, which will create an environment of guesswork, assumptions and inaccurate predictions when it comes time to make food safety and cost-recovery related decisions.

The lack of accurate product level data due to a poorly designed temperature tracking system will force the disposal of unadulterated perishables and create additional shrinkage and loss. These results are very expensive consequences that can be overcome with the implementation of a more robust monitoring process.

When you don’t need paralysis by analysis

Do you really need to know the entire history of every temperature at every point? Or does knowing that the products never exceed the regulated temperature for more than a certain period of time.

When you care and want your customer to know it.

Put a Timestrip in any temperature controlled shipment, no matter how small, and you’ll be letting the receiver know that you have guaranteed that it got to them in the condition you and they both expect.

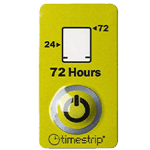

Timestrips are a simple visual indicator which requires no expertise to read, and is a quality seal that your cold chain has remained intact all along the way.

When you want simplicity.

The simplicity of the Timestrip allows for all users to easily read, understand and communicate information without having to deal with confusing electronics, readers, adapters and software installation. Not to mention having to deal with IT.

Timestrip indicators (unlike data loggers) can be launched, read and understood by every level of employee that may come in contact with product. From a front line dock worker to a back line manager everyone can quickly understand the quality of the product.