Operational Risk Assessment in the Logistics, Pharmaceutical & Food supply chains

The big word in the logistics and supply chain “world” is RISK, and a risk assessment being performed, or at least having a mitigation plan in place, is becoming part of many certification requirements, like ISO 9001, and other pending or recently introduced federal regulations.

It will be no surprise, I am sure, when I mention certain facts like – “Where humans are involved in a process there will be errors, and 90% plus of all supply chain errors are human errors”; but how do you avoid these?

Firstly, let me say there will always be Risk not only in the common elements of the supply chain but also and especially with the way that you handle any cold chain or temperature-controlled products.

So how do you manage these risks?

There are 4 common and accepted ways that Risk can be managed, or mitigated:

- Risk Avoidance: Changes made to your processes and players that ensures risks are no longer an issue.

- Risk Mitigation: Reduce the severity of the loss or prevent the likelihood of the risk from occurring.

- Risk Acceptance: Avoidance of a potential risk area is not possible or economically feasible, so it is acceptable and will not impact your business.

- Risk Deflection: After the risk has been identified and quantified, transfer that risk to the control of another player or partner in the process – maybe add it as a clause to be addressed in a vendor contract.

So how do you establish a Risk Mitigation Plan?

- Review and audit your supply chain to assess where risk does, or may exist

- Assess what the impact of these risks may be and create a list with the highest probability items at the top to address first

- Define your risk mitigation strategies for the highest-level items and work down the list from High to Low

- Implement the strategies and document them.

What else should I do, or know?

- Even though your Risk Management plan includes good SOP’s and WI’s make sure that people are adequately trained in these disciplines

- Conduct self-audits regularly

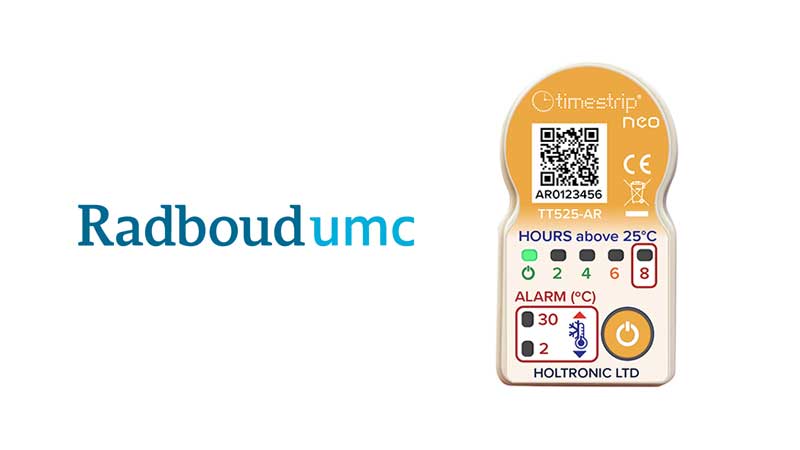

- The cost of a Cold Chain Monitoring device or solution, is far less expensive than the cost of disposal of a temperature compromised shipment

- All Quality Systems and Risk Aversion Plans should have one over-arching goal – Quality of Product and Consumer Safety!!!!

At Timestrip we are acutely aware of all kinds of risks that can exist in all kinds of supply chains from Pharmaceutical to Food and even beyond to special chemicals and laboratory testing time lines.

For a full range of our products please visit our products page