Ensuring Quality in the Cool Chain

In other articles, an overview has been given of monitoring cold chain temperature (including frozen) and at room temperature conditions. Here, the focus is on the range in between these two, referred to as the ‘cool chain’. While there is no precise range agreed for this, it is taken as typically 8° to 15°C (46°F to 59°F).

In today’s highly regulated pharmaceutical, food and biotech supply industries, maintaining products within defined temperature ranges is critical. In the cool chain, maintaining controlled conditions is essential for the stability, efficacy, and safety of many temperature sensitive products.

Ensuring that products remain within this range throughout the supply chain—during storage, transportation, and handling—can significantly reduce the risk of spoilage or loss of efficacy.

Why the 8°C to 15°C Range Matters

The cool chain is designed for products that require a slightly higher but still controlled temperature environment. This includes certain pharmaceuticals, vaccines, diagnostic reagents, tropical fruits, vegetables such as potatoes, as well as some chemicals.

Deviation from this temperature window, even briefly, can degrade sensitive compounds, resulting in compromised safety or therapeutic value.

Maintaining this range can be challenging. Shipments often pass through multiple hands and environments—from manufacturing facilities to warehouses, distribution centres, and ultimately, to the point of use. Each step presents a risk of temperature excursion, which must be monitored and documented.

The Role of Temperature Indicators

To address this, a wide range of temperature monitoring tools have been developed. These tools range from sophisticated data loggers to more accessible and cost-effective visual indicators. Among the most trusted in the industry are temperature indicators produced by Timestrip, a global leader in time and temperature monitoring solutions.

Timestrip’s Innovative Temperature Indicators

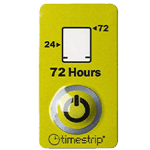

Timestrip offers a suite of temperature indicators, both liquid based and electronic, that provide a visual, irreversible indication of whether a product has been exposed to conditions outside of the defined temperature range. The products are compact, cost-effective and easy to use, making them ideal for integration into packaging or affixed directly to individual products.

For the 8°C to 15°C cool chain specifically, Timestrip offers the neo electronic indicator in custom form. These temperature breach indicators are very small and light, and are more accurate than liquid-based alternatives. They activate when a product is exposed to conditions above or below the safe window, and show the duration of the breach. Other indicators use chemical-based colour change technology, offering a simple visual cue in the form of a colour shift that clearly signals a temperature breach has occurred.

Some key advantages of Timestrip’s indicators include:

· Simplicity: Minimal setup—just peel and stick.

· Irreversible Evidence: Once a temperature breach is recorded, it cannot be reset or tampered with.

· Low cost – compared with conventional tools such as data loggers.

· Compliance Support: Helps businesses meet regulatory and quality assurance requirements.

· Customization: Solutions tailored for specific time and temperature thresholds.

Applications Across Industries

Timestrip indicators are widely used in industries where the cool chain is essential:

· Pharmaceuticals: Ensuring temperature-sensitive drugs and vaccines maintain their efficacy.

· Diagnostics: Protecting the accuracy of test kits and reagents.

· Food & Beverage: Monitoring the safe transport of specialty foods like cheeses and wines.

· Clinical Trials: Supporting the integrity of biological samples and investigational products.

As regulatory scrutiny increases and consumers demand higher levels of safety and quality assurance, reliable temperature monitoring within the 8°C to 15°C cool chain is more vital than ever.

Tools like Timestrip’s temperature indicators offer a smart, scalable solution that empowers supply chain stakeholders to maintain control and ensure compliance. With easy-to-use, visible temperature indicators, companies can ensure product safety, protect brand reputation and prevent costly product losses.