Understanding Cold Chain Monitoring

Safeguarding the Cold Chain: The Critical Role of Temperature Monitoring

In today’s global economy, the integrity of temperature-sensitive goods—ranging from pharmaceuticals and vaccines to fresh food and chemicals—relies on the effectiveness of the cold chain.

This complex logistical process involves maintaining a specific temperature range from production to consumption to ensure product safety, efficacy, and quality. As consumer expectations and regulatory standards grow ever stricter, temperature monitoring has become not just a safeguard, but a necessity.

Understanding the Cold Chain

The cold chain is a temperature-controlled supply chain that includes all stages involved in the storage, handling, and transport of perishable products. For pharmaceuticals, this might mean maintaining a range between 2°C and 8°C; while some vaccines will require much colder conditions - as low as -70°C. For frozen food, it could be -18°C or below. A single lapse at any point in the chain can lead to spoilage, reduced effectiveness, or even health hazards for end users.

Temperature excursions—periods when a product is exposed to temperatures outside of its safe range—are among the most critical risks in the cold chain. These excursions can occur due to equipment failure, human error, or unforeseen delays during transit. Hence, continual and visible temperature monitoring is vital.

Key Sectors Relying on Cold Chain Monitoring

Pharmaceuticals and Life Sciences

Temperature control is essential for maintaining the efficacy of many drugs, especially biologics, insulin, and vaccines. Even brief exposure to elevated temperatures can degrade active ingredients. The distribution of COVID-19 vaccines highlighted the importance of ultra-cold storage and the need for accurate, reliable monitoring tools.

Healthcare and Blood Products

Hospitals and diagnostic labs must store blood, plasma, and other biological samples at strictly controlled temperatures. Blood products, for example, must be kept within tight tolerances, and any breach can render them unusable. Compliance with standards like those from the FDA and WHO is mandatory.

Food and Beverage

Perishable foods—meat, dairy, seafood, frozen items, ready meals and food served on the move —must be transported in carefully controlled environments to prevent spoilage and protect consumers. Improper storage can result in bacterial growth, foodborne illness and product recalls.

Chemicals and Industrial Goods

Certain industrial products such as adhesives, polymers, and specialty chemicals, are sensitive to temperature changes. Deviations can impact their physical properties and shelf life, with costly implications for manufacturers and end users.

Cosmetics and Personal Care

Some cosmetics, especially those with natural or active ingredients, can degrade when exposed to heat. Cold chain solutions help maintain product consistency and extend shelf life.

The Role of Temperature Monitoring

Modern cold chain management relies on accurate data and simple, intuitive tools that alert handlers when conditions deviate from safe thresholds.

Monitoring helps stakeholders detect issues early, make informed decisions and maintain regulatory compliance. Additionally, robust monitoring can provide a traceable history of product conditions, important for quality assurance and auditing purposes.

Timestrip®: Smart Solutions for Cold Chain Monitoring

Among the leaders in cold chain temperature monitoring technology, Timestrip is a UK-based company specializing in simple yet highly effective temperature indicators. The Timestrip product range offers a wide variety of tools tailored for different cold chain needs, with a focus on ease of use, visibility and cost effectiveness.

Timestrip Temperature Indicators

Timestrip offers single-use, irreversible temperature indicators that are activated at the point of use. These include liquid-based indicators such as:

- Timestrip® PLUS: A range of indicators that monitor ascending temperatures across thresholds from -20°C to +38°C. These are ideal for pharmaceuticals, vaccines, and other perishable items, providing a clear visual indication if a temperature breach has occurred.

- Timestrip® Blood Temp 10: Specifically designed for blood transport, this FDA-cleared indicator shows if whole blood has been stored above 10°C for more than 30 minutes, helping ensure compliance with stringent medical regulations.

- Timestrip® Vaccine Monitor: Used during vaccine transportation and storage, this monitor helps verify that temperature-sensitive vaccines have not been exposed to potentially harmful heat.

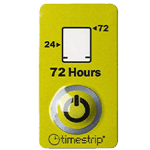

Timestrip Complete™

This advanced solution combines both upper and lower temperature monitoring, ideal for more complex supply chains. Timestrip Complete's visual display provides a simple indication of whether the product has remained within acceptable conditions and the cumulative duration of any breaches.

Electronic Indicators

For applications needing greater precision, Timestrip offers electronic temperature indicators such as the Timestrip neo range.

- Featuring very small and light form factors, the neo range includes TT525-AB, a Fridge Alarm indicator that monitors for excursions outside the 2-8°C range, and also indicates the duration for which a product has been above 8°C; an additional alert is provided at

-0.5°C. - Timestrip’s TL52 Micro Data Logger stores time and temperature data in the 2-8ºC range and users can download reports to a temperature monitoring app.

Stored time and temperature data can be essential for audits and regulatory compliance, especially in high-value pharmaceutical shipments.

Supporting Compliance and Confidence

With global regulatory bodies enforcing rigorous standards for cold chain management, having reliable monitoring tools is essential. Timestrip temperature and time indicators support Good Distribution Practice (GDP), and provide auditable proof of proper handling throughout the supply chain.

Beyond compliance, Timestrip’s solutions instill confidence among stakeholders—from manufacturers to healthcare providers and end consumers by visually confirming product integrity.