Freezer Cold Chain

In the global cold chain, maintaining precise temperatures is not just a regulatory requirement—it’s a matter of safety, efficacy and quality. This is particularly critical in the freezer segment of the cold chain, where products such as vaccines, biological samples and perishable foods may need to be stored and transported at sub-zero temperatures.

While taxonomies vary, the ‘frozen’ segment typically covers the temperature range -16°C to -20°C, while ‘deep freeze’ refers to temperatures that can go as low as -80°C. In some cases, such as food products, the goods must be protected from freezing, with the critical temperature then being 0°C.

The deep freeze segment includes products as diverse as seafood and vaccines, while the frozen segment typically includes meat, some dairy items and bakery goods.

The Importance of Monitoring Freezing Conditions

Temperature excursions in the freezer part of the cold chain can be highly significant. Whether it's a shipment of frozen food or a batch of COVID-19 vaccines, exposure to temperatures above the designated freezing threshold—even briefly—can result in spoilage, loss of efficacy, or complete product failure. Monitoring devices are essential for providing real-time or retrospective signals that can confirm whether the product has remained within the required temperature range.

One of the most effective means for ensuring integrity in this segment is the use of temperature indicators. Timestrip®, a UK-based company leading in this space, specialises in time and temperature monitoring solutions that are simple, cost effective and highly reliable.

A particular danger is with goods that have thawed and then re-frozen, as visibly there might be no indication of the breach. An irreversible temperature indicator travelling with the goods is indispensable for providing a suitable visual alert to these conditions.

While data loggers are often used for continuous monitoring, they can be expensive, require setup, and may not be practical for every leg of the journey. Timestrip temperature indicators offer an immediate, visual way to verify whether freezing conditions have been maintained or breached. Being small, light and low cost, Timestrip indicators can be attached at product or packaging level.

Timestrip’s Solutions for Freezer Temperature Monitoring

Timestrip PLUS™ Freezer Indicators

- Frozen food shipments

- Pharmaceutical products requiring sub-zero storage

- Biological samples in clinical trials

The Timestrip PLUS™ Freeze series eliminates the ambiguity that sometimes accompanies digital readings by offering a clear, visual cue that a freeze condition was not maintained.

Timestrip Descending Freeze Indicator

Timestrip Descending Freeze Indicator

This indicator is designed to monitor whether a product has been exposed to freezing temperatures—rather than breaches above freezing. This is particularly important for vaccines and drugs that must not be frozen. Timestrip Descending temperature indicator can be used to ensure that products have not been accidentally frozen during transport or storage, especially in regions where cold chain infrastructure may be inconsistent.

Timestrip neo Freeze Alarm

Timestrip neo Freeze Alarm

The electronic Timestrip neo Freeze Alarm is designed for products that are sensitive to freezing, and provides a visible freeze alert if the ambient temperature drops below 0ºC for 30 minutes; it shows a further alert at 60 minutes.

More accurate than liquid indicators, electronic indicators have been specially developed to combine ease of use with a very small and light form factor. All Timestrip neo indicators are suitable for pack level monitoring with both time and multiple temperature settings.

Vaccine Freezer Monitor ‘VFM -7⁰C’

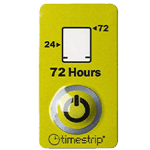

A Timestrip irreversible temperature indicator helps healthcare professionals avoid wastage of vaccines. Travelling with packs of vaccine vials, the VFM is activated just when monitoring is required.

The indicator is started simply by pressing a button on the back, and can then quickly be placed in the packaging along with the frozen vaccine vials. From then on, VFM -7⁰C follows the temperature precisely, and shows a clear alert if temperatures rise above -7⁰C. In this case, the vaccine should be discarded or sent for examination.

A built-in window shows the duration of the breach up to 72 hours, but should temperatures rise well above the -7⁰C set point, the window will fill faster, mirroring the effect of temperature on delicate vaccines.

Why Choose Timestrip for Freezer Cold Chain Monitoring?

- Affordability: Compared to electronic data loggers, Timestrip’s indicators are cost effective and ideal for single use applications.

- Ease of Use: These indicators require no training or equipment. They activate with a simple press and display changes visibly.

- Customization: Timestrip offers custom temperature thresholds and response times, allowing precise tailoring to different regulatory and product needs.

- Regulatory Compliance: Timestrip indicators help companies comply with industry standards such as FDA, WHO, and EU guidelines by providing a clear audit trail of temperature exposure.

Applications Across Industries

Timestrip’s freezer temperature indicators are used widely across multiple sectors:

- Pharmaceuticals: Ensuring vaccine stability during transport.

- Food and Beverage: Confirming that seafood, meat, or dairy have remained frozen.

- Life Sciences: Protecting biological samples during clinical trials and laboratory studies.

Application example - Seafood Preservation

Maintaining the right temperature is crucial for preserving the freshness and quality of seafood. Seafood products are highly perishable and susceptible to spoilage caused by bacterial growth, enzymatic reactions, and oxidation. Temperature abuse can accelerate these processes, leading to the growth of harmful bacteria and the production of toxins, resulting in a significant risk to consumer health.

The Timestrip Seafood Temperature Indicator monitors the ascending temperatures of fresh seafood in reduced oxygen packaged seafood where C. botulinum toxins can develop undetected above 3.3°C / 38°F. Timestrip neo Freeze Alert gives notification of unwanted freezing conditions, for example after thawing.

FDA guidance requires fish importers and processors to develop and implement a Hazard and Critical Control Point (HACCP) plan for addressing supply chain dangers including temperature abuse. With the Timestrip Seafood Indicator, seafood handlers know just by looking at the indicator whether a temperature breach has occurred.

As the cold chain continues to become more complex, simple, effective solutions like those offered by Timestrip are invaluable. In the environment of freezer storage and transport, temperature indicators serve as reliable sentinels—guarding against costly and dangerous temperature breaches. Whether it’s a pharmaceutical shipment or frozen food consignment, Timestrip ensures peace of mind with a single glance.

Timestrip Descending Freeze Indicator

Timestrip Descending Freeze Indicator Timestrip neo Freeze Alarm

Timestrip neo Freeze Alarm