Cold chain challenges and opportunities for air transportation

Whether it’s Chilean blueberries for breakfasts in London, French-made polio vaccines for use in Malawi, or Mauritian sea bass for restaurants in the Big Apple, the chances are that all these cold chain perishables have been transported by air.

Indeed, thanks to our increasingly connected world and rising incomes in developing nations, consumers across the globe are opting for perishables produced far from where they will be consumed. Since 2010 in India for instance, rising per capita incomes have led to an increase in the consumption of frozen food, meat, fish, canned and instant food items, as well as a greater acceptance of frozen vegetables.

Similar trends have been noted in China, where in increasing numbers more affluent consumers are opting for imported foodstuffs, especially seafood.

Strong growth for cold chain logistics

For cold chain pharma products, the figures are startling. In its annual Biopharma Cold Chain Sourcebook, Pharmaceutical Commerce estimates the global volume of 2017 cold chain products at $283 billion, out of a total market of $1.17 trillion, and growing at approximately twice the rate of the overall pharma market.

The International Air Transport Association (IATA), which supports aviation with global standards for airline safety, security, efficiency and sustainability, estimates that immunization prevents 2.5 million deaths every year and sees air cargo as critical for flying short shelf-life vaccines to their destination in time to be effective.

Air transportation is also critical to the economy of many regions, notably fruit‐ and vegetable‐producing countries in Africa that ship most of their produce to developed markets.

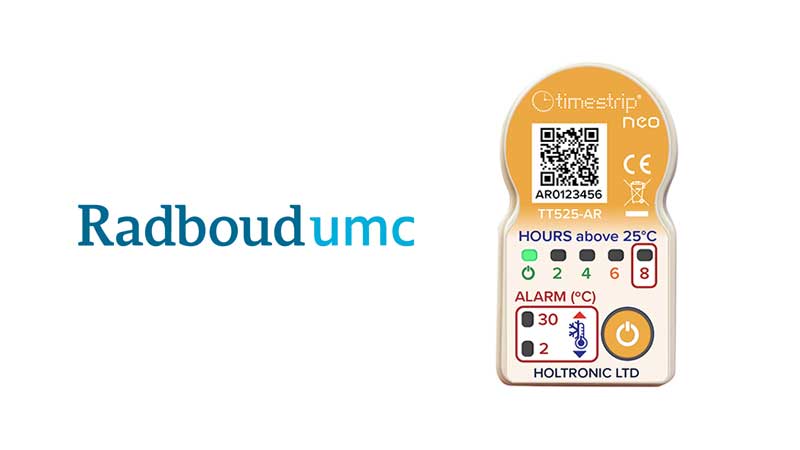

Time and Temperature Indicators (TTIs) play a key role in this process, by providing clear and unambiguous data as to whether any cold chain breaches have occurred during transit, and if so, how long they lasted. Moreover their use with certain products in certain markets are mandated by regulatory authorities, such as by the FDA for seafood imports into the US.

Managing complex logistics

That said, the transportation of cold chain perishables by air is highly complex and prone to numerous situations where temperature breaches can occur. In a study for the air transporter IAG Cargo, researchers found that over half of all temperature deviations occurred during transportation.

This data is supported by findings of the World Health Organisation (WHO), which says: “The greatest and most frequent vulnerability to temperature exposure occurs on the airport tarmac when goods are exposed to the elements before aircraft loading, or during unloading.”

Research however points to cold chain logistics managing these situations effectively for some time now. A 2012 study of Icelandic fish exported to the UK and France showed that despite poor temperature control during storage and ground operations at the airports before and after the flights, relatively a moderate increase in the temperature of the fish were recorded: the pallets of food were subjected to ambient temperatures above 10°C as well as solar radiation for several hours, but the temperature of the fish rose by less than 2°C. This was explained by the transportation of the fish inside polystyrene boxes, which were kept cool with ice inside the boxes.

It’s important to stress though that in these sorts of situations it’s only the use of temperature monitoring tools such as irreversible TTIs inside the boxes on the transported items themselves that a stakeholder can know whether potentially damaging temperature breaches have occurred.

Food loss epidemic

Nevertheless, despite much progress and professionalisation in cold chain logistics, certain problems remain difficult to resolve. One of the main costs with the transportation of perishable products such as fruit and vegetables is wastage due to spoilage related to inadequate temperature management during transit. Estimates vary as to what this amounts to, but most data suggests it is in the region of 33%.

According to the United Nations’ Food and Agriculture Organization (FAO), this wastage should be viewed as a “food loss epidemic”, which it values at about $1 trillion each year. Added to this are related environmental costs: wasted water used to produce food that is never eaten equal to the water needs of Africa, and CO2 emissions equivalent to removing every car off the road across the world.

It is hard to imagine any industry would tolerate 30-40% inefficiency.

Food bacteria grow best between 5°C and 60°C, which explains why keeping perishable products cool, cold, frozen or deep frozen is the only way to guarantee product quality and shelf-life as it arrives at the end of a transportation process.

Customers of air transport providers for perishables are well aware of this. In a survey of their various concerns, the three greatest were recorded as:

- the expertise of handling personnel

- appropriate temperature monitoring

- traceability

What is remarkable about these concerns is how they very much match those of the healthcare sector and it would seem that moving forward, it will be the lessons learnt from transporting pharma products, that could help avoid the massive cost of food spoilage during transit.

In a conference in Dallas, Texas, last year organised by the Netherlands-based Cool Chain Association, chairman Stavros Evangelakakis suggested applying healthcare industry standards to perishables would lead to wastage being “dramatically lowered”.

A post conference statement went on to stress the need to “treat perishable cargo with the same care, respect and transparency as pharma”, adding that this would be “crucial” for new and emerging markets such as South American and Africa.

Potential “quadruple win” for cold chain logistics

A recent study reported on in The Guardian highlights the huge benefits proper cold chain management can bring to the transport of perishable foods.

A carrier in India field tested cold chain equipment with a local grower for the transport of fruits in refrigerated trucks from Punjab to Bangalore, a 1,600 mile-trip over rough roads in high temperatures.

The results were significant:

- a one-week shelf life increased to two months

- profit increases by up to 23% for all the supply chain actors

- post-harvest food loss reduced by 76%

- greenhouse gas emissions reduced by 16%, excluding the significant reduction of emissions from food loss

Blueberries in January

One of the massive economic benefits of effective cold chain management is how it enables the creation of new markets.

In most countries, blueberries used to be only available at specific times of the year. The situation changed dramatically in the 1980s, with Chile harvesting blueberries from October until late March and exporting these to the US.

Today thanks to climate-controlled storage and transport technologies, the fruit is available year-round in many regions, buoyed on by the rebranding of the fruit as a “super-food”.

Today, the US is the world’s largest producer of blueberries, followed by Canada, Poland and France. Meanwhile in the UK, 2010 was the year blueberries overtook raspberries as the country’s favourite soft fruit after strawberries.