The Fresh Cold Chain

Time and distance are the twin challenges when managing cold chain logistics for the transportation of fresh food perishables

Fruit and vegetables, packaged salads, dairy produce, eggs and even flowers – consumers the world over depend on supply chains that can bring perishable goods to retailers’ shelves speedily and in the best possible condition. Their instantly made purchasing decisions depend on products looking as appealing and unblemished as they do in promotional advertising.

At Timestrip, we see this every day. One of our aquaculture clients uses our Irreversible Time and Temperature Indicators in the export of seafood to the US market. He reports that how his products look upon arrival directly impacts on whether a delivery is rejected or not. His use of Timestrip smart labels ensures that his cold chain management processes guarantee not only that his products are safe after transport, but also look fresh to the end-user. (Read our Ferme Marine de Mahebourg case study)

Moreover, this need for efficient transport processes that guarantee product quality at the point of sale is playing itself out against a backdrop of rising worldwide consumer demand for perishable goods as per capita incomes rise in major markets such as China and India.

A general rule of thumb in the global food trade is that lower per capita income nations tend to import mostly grains, while higher per capita income nations import a wide range of cold chain perishables. So, while 70% of foods consumed in the US are managed by cold chain processes against only 25% of the meat and 5% of the fruits and vegetables in China, for the latter these figures are rising rapidly.

Also, within developed markets, the demand for perishables is rising. According to Winnesota Regional transportation, the US refrigerated transportation market on which the sale of perishables depend is growing at a rate of around 12.5% per annum, with strong projected growth in the coming years.

Projected annual growth in global cold chain to 2020 - 13.9%

Fresh produce shelf-life time spent in transit- 50%

Source: Logistics Bureau

Although regulation around safety is an important factor in the growth of cold chain transportation, globalisation and innovation play a far more important role. Technological progress around refrigerated transport makes it possible for less developed economies to sell their perishable produce in far away markets.

Complex international supply chains

As soon as a flower is picked or a fruit and vegetable is harvested, it begins to rot. Time and distance are thus the twin challenges of the fresh cold chain.

In fact for some produce such as Guatemalan bananas that picked when they are green, this biological process occurs during transit thus ensuring they arrive at retailers in the EU and the US in a saleable condition.

To avoid product spoilage, speed is the number 1 priority. Cold chain processes are therefore equipment and technology intensive in order to prolong freshness so consumers get to buy saleable produce.

Other considerations include:

- product sensitivity to weather and other naturally occurring disruptions

- the maintenance of sound sanitary practices from producer to retailer

- the requirement of specialised handling and packaging

- accurate labeling and traceability

Faster supply chains

An increasingly common feature of making perishables supply chains faster is for major supermarkets to take total control of this process with acquisitions of farming production facilities and the development of close business relationships with growers.

In the UK, the supermarket chain Morrisons is also one of the country’s biggest food manufacturers, with over 20 nationwide food production and distribution sites. The group says that more direct links with its farmers enable it to deliver the freshest food and best value to its customers.

Vertical supply chains also allow for growers and farmers to earn more from their produce. This happens in France with the supermarket chain Intermarché whose close relationships with dairy farmers ensure that they are paid 50% of the retail sales price of a litre of branded milk.

From farm to supermarket shelf

The Leckford Estate in Hampshire, southern England, is the Waitrose supermarkets farm that supplies its produce to Waitrose stores across the UK

Keeping the fresh cold cold chain cool

Although speed is essential in ensuring that the transport and delivery of perishables avoids spoilage, temperature control is another vital component in guaranteeing fresh cold chains.

“Maintaining the cold chain is one of the most effective ways to ensure safe, quality food”

Jorge Hernandez, Senior VP, food safety and quality assurance, U.S. Foods

The complexity of the required processes has led to the food companies working increasingly with specialist third party suppliers and the requirement of suitably qualified personnel.

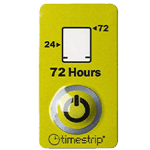

Another key cold chain area for temperature monitoring revolves around equally specialist technologies, such as RFID tags that record and forward real-time temperature data, real-time GPS tracking that provide visibility of shipment progress, and a range of high-tech time and temperature monitoring solutions.

Avoiding waste due to spoilage

Fresh produce spoils easily and in many cases this is only identified at the very end of the transportation cycle, leading to either shipments being rejected or consumers claiming refunds from retailers. Moreover, apart from waste caused by the spoilt produce, further costs are incurred related to transporting these products that will never be consumed.

For companies, these have a big impact on their financial results. Timestrip Irreversible Time and Temperature Indicators are currently being used by a number of companies to address this issue. In the US for instance, the rail carrier Amtrak has integrated Timestrip products to successfully reduce food waste of its on-board catering services. Read our Amtrak case study.

At an industry level, a new vision about how to reduce these costs is around the establishment of "lean practices" whereby handling by various stakeholders in a perishables supply chain are kept to the very minimum. This is part of the thinking behind supermarkets taking control of food production mentioned above.

A strategy in this area includes a focus on direct-stores deliveries that avoid traditional centralised distribution methods and the maintenance of smaller local fresh produce warehousing much closer to retail outlets.

Significant savings can be also generated with appropriate packaging that protect fragile perishables against damage and innovative materials that actually extend the life of produce by controlling its life-cycle with the use of ripening agents such as ethylene gas.

This can involve speeding up the ripening process with innovative packaging containing ethylene gas capsules that can ripen fruit on demand, and ethylene gas that is used to ripen green bananas during transportation. It can also involve slowing down the ripening process with the use of ethylene absorbers that are added to fruit packaging.

A growing area of cost savings in fresh supply chains is the use of returnable plastic crates (RPCs) that can be used many times.Their ergonomic design allows for space-saving stacking, safer handling and ventilation and draining hat reduces in-transit spoilage. Plus with so-called "one-touch merchandising", RPCs placed directly onto shelf displays,further reducing handling.

They also have an impressive environmental record: a 2013 study found that RPCs generate 82% less waste, consume 92% less water, cause 76% less ozone depletion and require 49% less energy.

Managing the fresh cold chain

Franck Artis is the Singapore Branch Manager of Food Distribution Pte Ltd. He says:

For perishables such as dairy produce, it is essential that the cold chain is not breached during transportation, with an ideal temperature range of 3°C to 4°C. This is just as much for product quality as for food safety. Normally this must involve some kind of refrigerated transport.

For domestic transport such in France, this involves refrigerated lorry deliveries direct to retail outlets or (often regional) distribution platforms that have dedicated cold rooms for temporary storage. For export, this can involve either a transporter operating door-to-door processes or alternatively outsourcing this function to third-party cold chain logistics suppliers.

A key feature of cold chain management during the maritime transport of perishables is the ability of transporters to supply accurate and complete temperature data that shows that the cold chain has not been breached. This can mean using reefer containers with temperature tracker boxes that monitor and control the temperature inside the containers, and log and respond to any breaches, say, in the event of a temporary power outage.

The economics of the transport of perishables dictate that temperature monitoring tools such as Irreversible Time & Temperature Indicators would only be used for high added value items, such as caviar, rather than a carton of yogurt or milk.

For perishables such as flowers, avocados, bananas and tomatoes, transit time is used a ripening period to ensure that when they arrive at their final destination (retail) point, they are fit for sale.

The advent of the banana cold chain

Bananas make up the largest share in the transport of perishables, equivalent to approximate 20% in volume and worth some US$8bn in 2013.

Exact figures of global banana production are difficult to determine as globally only 15% of production (which include plantain) is exported and much of what is not exported is produced by small or very small growers.

Nevertheless, refrigerated cargo (aka reefer) ship technology has been an important driver in the cold chain technology development. The first reefer ship for the transport of bananas was developed in the US in 1902 by United Food Company.

Up until that point, bananas were a highly exotic fruit and very much a luxury item in non-banana producing nations.

Today, it is one of the world's most consumed fruit and due to its distinct ripening process, the trade and transportation of this produce has led to distinct term in cold chain logistics – the so-called 'banana cold chain'.