Transport and Storage of Pharmaceutical Products – Challenges and Responses

1. Issues in Pharma Transport

Several sources have reported on the issues with biopharma cold chain logistics, and in particular, the need for effective temperature monitoring throughout the product cold chain.

1.1 Cold Chain Logistics in Temperature Controlled Supply Chain

In 2019, Pelican Biothermal conducted a broad survey of key opinion leaders across the industry. Ref 1 The survey highlights several transport and logistics-related issues in the temperature-controlled biopharma supply chain:

- In the survey, about 44.6% of respondents reported multiple temperature excursions per year, and 16% said excursions happened monthly.

- The excursions are not trivial: about 41% of such excursions exceeded a 4°C deviation, and 21% exceeded °C.

- The key drivers of complexity were said to be:

- “Increasing quality demands” — more delicate biologics and sensitive products demand tighter tolerances.

- “Expanding distribution range” — more products are shipped across longer distances and more climatic zones, increasing risk.

- Focus on optimising total cost of ownership (TCO) means some players may trade off robustness of logistics for cost.

- The survey also notes that logistics failures cost the industry billions; for example, an estimate of ~US$35 billion annually lost for biopharma due to cold-chain failures.

- Transport modes: The survey highlights the importance of diversifying transport (air, ground, sea, rail) but also that more climatic zones and longer legs increase risk of excursion.

1.2 The document “Guide to Shipping Pharmaceutical Products” by Couriers & Freight reported (Ref 2):

Regulatory burden: In Australia, shipments must comply with the Therapeutic Goods Administration (TGA) and the Australian Code of Good Wholesaling Practice. Documentation must include batch numbers, expiry dates, temperature logs, handlers, times and locations.

Packaging and transport interplay: Even the right packaging can’t compensate for poor transport conditions (e.g., delays, ambient heat, un-conditioned vehicles). The article emphasises insulated containers, gel packs or phase-change materials.

Temperature-sensitive items (such as vaccines, biologics, insulin) require strict control; a ‘small mistake’ in the chain may spoil an entire shipment and risk patient safety.

Transport aspects specifically called out:

- Road vs air: choice of carrier and mode matters; real‐time tracking and visibility help ensure the shipment stays within the required temperature envelope.

- Last-mile’ risks: from distribution hub to patient or pharmacy is vulnerable, especially in remote or hot-climate zones.

- Compliance of handlers: Cold chain standards must be met for temperature‐sensitive products; if the chain breaks, the medicine may become unsafe or lose efficacy.

1.3 Summarised transport-risk themes

From the above, the key transport-related risks in pharmaceutical cold chain logistics can be summarised as:

- Temperature excursions during transport (delays, ambient extremes, inadequate packaging or conditioning, vaccine storage during power outage)

- Extended distribution range and climatic variability, increasing the number of handovers, transport modes, and thus points of risk

- Inadequate monitoring or visibility of temperature in transit (i.e., shipments may be sent without sufficient real-time insight)

- Packaging and transport interaction: even good packaging may fail if transportation conditions (e.g., vehicle uncontrolled environment, delay) are poor

- Regulatory/compliance burden and documentation which if not properly handled, means risk of non-compliant shipment, potential product recall or waste

- Last-mile delivery especially in challenging geographies (Australia’s size and remote areas as example) adds further risk

- Cost pressures causing trade-offs between robust logistics and cheaper alternatives, potentially compromising quality

2. How Temperature Indicators Can Assist in Transport Risk Mitigation

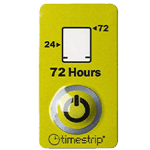

Temperature indicators, such as those from global supplier Timestrip, offer a practical tool for monitoring and validating pharmaceutical temperature exposure during transit and especially in transport segments.

2.1 Overview of Timestrip indicators

The Timestrip temperature monitoring range includes single-use, irreversible, ‘smart’ indicators that provide indication of cumulative time above a specified threshold temperature (for example 8°C) by movement of a coloured dye, or by LED lamps.

They are lightweight, low cost, and can be applied directly to a package or pallet. They are available in a wide range of threshold temperatures (-20°C through +38°C) and various run-out windows (hours to months) to suit different shipping requirements. They provide traceability via unique serial number printed on each indicator.

The unique Timestrip neo is a family of electronic indicators with even greater accuracy than liquid-based alternatives.

2.2 How temperature indicators support safe transport

Immediate visual verification: At the end of transit, the receiver can instantly see whether the threshold was exceeded and for how long. This aids decision-making: e.g., accept or reject the shipment.

Lower-cost per package monitoring: Because they are low cost and single-use, indicators can be deployed at carton or unit level, not just pallet level, giving finer granularity of monitoring e.g. inside a large refrigerated vehicle.

Transport segment risk monitoring: Indicators can be placed on packages at dispatch and retained through transport, providing evidence throughout the transport chain and especially helpful for segments with higher risk (e.g. road transport in high ambient temperature.

Complement to real-time monitoring: While expensive loggers or telemetric systems capture full profile, indicators offer a cost-effective check, readable by all levels of personnel, and are especially useful for ‘last mile’ or smaller shipments.

Regulatory / documentation support: Having a physical, irreversible indicator showing exposure provides evidence for compliance (reduced risk of dispute or non-compliance).

Encourages packaging/transport improvement: When recurring excursions are detected via temperature indicators, logistics managers can identify weak links (transport leg or packaging fail) and take corrective action.

Mitigating climatic risk: In environments where ambient temperatures can soar and transport distances are long, indicators alert to conditions where ambient heat may penetrate packages or cooling systems fail.

2.3 Practical deployment guidance for transport

Some tips for effectively using temperature indicators in the transport of pharmaceutical products:

- Choose the correct threshold: match the indicator’s threshold to the product’s temperature requirement (e.g., 2-8 °C for many biologics).

- Use multiple indicators per shipment if the load is large or there are packaging zones / layers that might behave differently.

- Place indicators in the most temperature-vulnerable positions e.g. near outer walls of the pallet, near the bottom of stack, near top if ambient heat enters.

- Activate the indicator properly before shipping and record its serial number in shipment documentation for traceability.

- At receipt, inspect the indicator: if it shows excursion beyond acceptance criteria (time above threshold or full run-out), reject or quarantine the shipment.

- Analyse data/trends: Be alert to repeated excursion patterns — for example a particular carrier leg, or particular packaging type failing — and then review carriers, packaging, mode of transport, route, or handling.

- Integrate indicator reading into standard operating procedures and documentation: e.g. carrier handed off, receipt certificate includes “Indicator serial XXX shows no breach – shipment accepted.”

- Ensure packaging and transport conditions are correctly engineered: indicators are not a substitute for good design but a validation tool. If many indicators show breaches, packaging/transport scheme must be re‐assessed.

3. Conclusion and Recommendations

In the transport of temperature-sensitive pharmaceutical and biopharma products, the risks are real and significant: surveys show that many organisations experience multiple temperature excursions annually, often of substantial magnitude. Transport is a key part of that risk matrix, especially given longer distribution distances, varied modes, climatic extremes and multiple hand-offs.

Temperature indicators such as Timestrip provide a practical, cost-effective way to monitor and manage the transport leg of the cold chain, offering visual evidence of exposure and enabling better oversight, decision-making, traceability and corrective action.

What are the recommendations for pharmaceutical shippers?

Incorporate temperature indicators as part of your transport packaging and monitoring toolkit, especially for shipments via high-risk routes (hot ambient, long road legs, remote destinations).

Ensure that transport mode, carrier choice, route, and packaging are matched to your product’s sensitivity — use Timestrip indicators as a validation mechanism.

Use indicator data to drive continuous improvement: if indicators repeatedly show excursions, change packaging spec, shorten transit, change carrier or route.

Embed indicator usage into your standard operating procedures and regulatory documentation so that indicator readings form part of the batch shipment record.

For last-mile deliveries (for example remote pharmacies or direct patient distribution), where risks are high, indicators may be especially valuable to provide confidence that the cold chain held throughout.

Contact us to discuss pharmaceutical temperature solutions today

Refs:

1. Peli BioThermal 2019 Biopharma Cold Chain Logistics Survey

2. Guidance article from Couriers & Freight. aircargonews.net