The Silent Guardians of Quality: A Comprehensive Guide to Time and Temperature Intelligence

Table of Contents

- Why temperature and time monitoring matters

- Liquid Based Indicators

- Electronic Indicators

- Healthcare and Life Sciences Industry

- Food Safety and Logistics Sector

- Time Monitoring - Beyond the Cold Chain

- The Strategic Value of Indicators

- Usage and Best Practices of Time Temperature Indicators

- Sustainability and the Environment

- The Timestrip Ethos

- Future of Time and Temperature Monitoring

1: Introduction: Why Temperature and Time Monitoring Matters

In the intricate web of the modern global economy, products travel further and faster than ever before. From salmon caught in the North Pacific Ocean to a life-saving vaccine administered in a rural clinic in Africa, the journey of a product is fraught with invisible perils. The most insidious of these is environmental fluctuation. A spike in temperature on a tarmac, a freezer failure in a warehouse, or a simply forgotten maintenance schedule can render valuable goods useless, or worse, dangerous.

The Invisible Challenge of Modern Logistics

For two decades, Timestrip has stood as a vanguard against this invisible threat. With a base in the United Kingdom and operating on a global scale, Timestrip has pioneered the development of smart indicators that provide an unblinking eye on the conditions of products. With over 20 years of experience in designing and manufacturing unique monitoring solutions, Timestrip has evolved from a manufacturer of simple indicator labels into a global leader in time and temperature intelligence.

This article delves deep into the ecosystem of Timestrip, exploring the sophisticated yet accessible technology behind their products, their diverse applications across critical industries, and the impact they have on safety, quality, and sustainability.

2: The Science of Simplicity – Liquid-Based Indicators

At the heart of Timestrip’s product portfolio lies a technology that is deceptively simple yet scientifically ingenious: the liquid-based indicator. The irreversible liquid-based indicator remains a popular solution due to its low cost, reliability and ease of use.

How Liquid-Based Indicators Work

Liquid-based indicators rely on predictable physical processes rather than electronic sensors. The core technology typically involves a safe, food-grade coloured liquid (dye) housed in a sealed blister. This blister is held adjacent to a specialized micro-porous membrane.

- Indicator Activation: The device is attached to the product to be monitored, typically using a self-adhesive backing, and activated manually by squeezing a small button or blister. This action breaks an internal seal, bringing the liquid into contact with the membrane.

- Temperature Monitoring Indication: The dye moves through a membrane at a precise, calibrated rate. This movement is visible through a viewing window as a colour change. The indicator is then monitoring the ambient temperature continuously. The distance the dye travels corresponds directly to the cumulative time the product has been exposed to the excessive temperature. Any breaches in expected conditions can be immediately viewed in the window.

Irreversibility: The Key to Trust

A crucial feature of Timestrip’s liquid indicators is irreversibility. Once the dye has moved along the scale, it does not return to its original position, even if the temperature drops back to safe levels. This prevents ‘masking’ of thermal damage. For example, if a pallet of frozen food thaws and then refreezes, a standard thermometer might show the current safe temperature, hiding the past danger. A Timestrip indicator, however, will permanently display the breach, providing an unalterable audit trail.

Timestrip PLUS indicators monitor ascending temperature breaches. They are available for a wide spectrum of thresholds, from frozen conditions (e.g. -20°C) to varying room temperatures (+38°C). They feature ‘run-out windows’ that can track breaches for periods ranging from one hour to several days. This allows operators to make informed decisions—a brief 10-minute excursion might be acceptable, whereas a 4-hour breach requires disposal.

3: Electronic Indicators

While liquid temperature and time indicators offer great simplicity and cost-effectiveness, certain applications demand greater accuracy, data storage and connectivity. Recognizing this, Timestrip offers a range of electronic indicators.

Timestrip neo and neo Multi

The Timestrip neo platform represents a bridge between visual simplicity and electronic precision. These compact, electronic indicators utilize LED lights to provide instant status updates and are accurate to +/- 0.5 °C. For instance, a green light might flash to indicate ‘all is well’, while a red light warns of a high-temperature breach, and a blue light warns of a freeze event. The precise meaning of the various lights depends on the neo product specified and its intended use.

Recently, the company introduced the Timestrip neo Multi-X, the world's first multiple-use temperature indicator of its kind. Unlike single-use disposable units, this device can be reset and reused, making it a powerhouse for closed-loop logistics systems where containers are returned and reused, such as in train catering (e.g. Rail Gourmet) or dedicated medical courier services.

Despite their high-tech nature, these electronic products retain the Timestrip DNA: they are small, lightweight (reducing shipping costs), and simple to use.

4: Sector Focus – Healthcare and Life Sciences

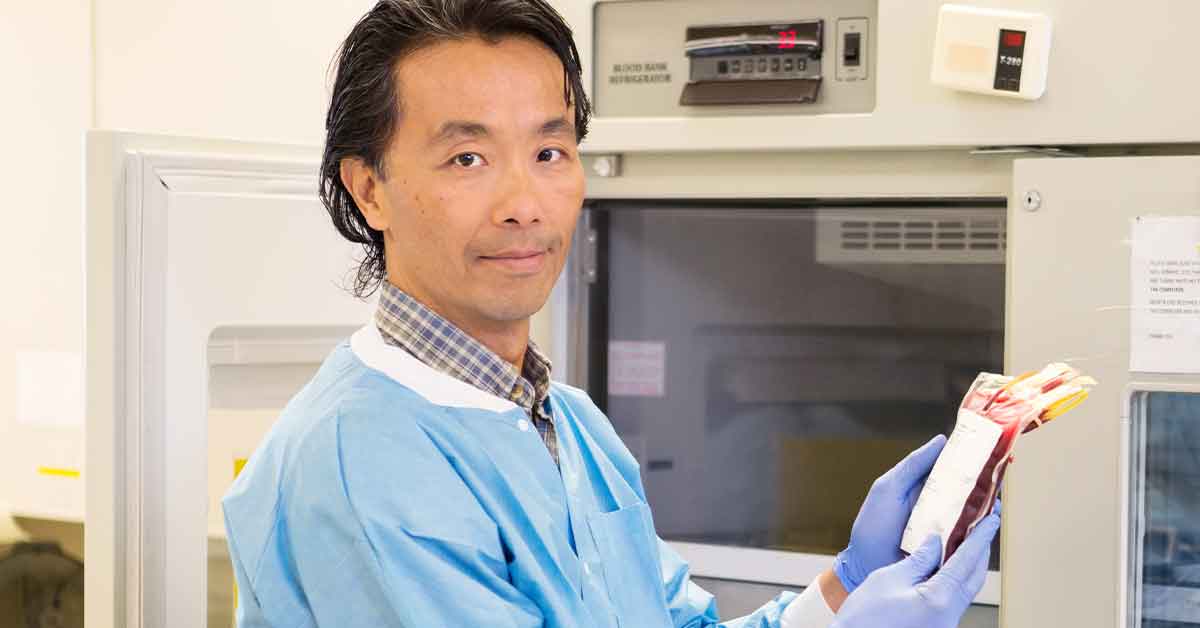

There is perhaps no sector where the stakes are higher than in healthcare. A compromised blood bag or a denatured vaccine is not just a financial loss, it is a patient safety risk. Timestrip has developed specific solutions that have become industry standards.

The Blood Temp 10 Story

Blood is a precious and fragile resource. The Timestrip Blood Temp 10 (BT10) is a specialized indicator designed to monitor the temperature of red blood cells during transportation and temporary storage.

- The Challenge: Blood bags must be kept cool. If the core temperature rises above 10°C, the risk of bacterial growth increases significantly. Conversely, returning a bag to the fridge that has been out too long can compromise the entire stock.

- The Solution: The BT10 is an FDA 510(k) cleared medical device. It requires no pre-conditioning (it can be stored at room temperature) and is activated with a simple button press upon application to the blood bag.

- The Benefit: If the blood bag’s temperature exceeds 10°C, the indicator window turns blue. This provides a binary, unambiguous "Go/No-Go" decision for clinicians. It reduces the unnecessary wastage of blood (by confirming blood is safe to return to storage if the indicator hasn't triggered) and ensures patient safety by flagging potentially unsafe units. Traceability is ensured through unique serial numbers on every label.

Vaccine Monitoring

From the factory to the patient's arm, vaccines traverse a perilous ‘Cold Chain’. The World Health Organization estimates that up to 50% of vaccines are wasted globally, largely due to temperature excursions, although this figure is much lower in more developed countries. Timestrip’s range of vaccine monitoring indicators help close this gap. They provide visual assurances that vaccines have remained within their required temperature bands. For example, the TP498 monitors the time a vaccine spends after being taken from the freezer (up to 2 hours), while the TP496 tracks how long a vaccine has been kept in refrigerated conditions (2°C to 8°C).

Critically, Timestrip also offers Descending Temperature Indicators (like the Freeze Check). For many vaccines (and insulin), freezing is just as destructive as heating. These indicators alert users if the temperature drops below 0°C, avoiding the administration of crystallized, ineffective vaccines.

Clinical Trials and Pathology

In the world of clinical trials, data integrity is paramount. Specimens transported to labs for analysis must be kept within strict conditions to ensure valid results. Timestrip indicators are frequently used on transport boxes for biological specimens, providing the "chain of custody" proof required by regulators.

5: Sector Focus – Food Safety and Logistics

The modern food supply chain is long, complex, and vulnerable. Food travels from farms to processing plants, distribution centres, retailers, and finally to the consumer's home. At every stage, the ‘Danger Zone’ (4°C - 60°C) offers a breeding ground for bacteria.

Seafood and the Botulism Threat

Seafood presents a unique challenge, particularly regarding clostridium botulinum. This bacterium thrives in low-oxygen environments—common in modern vacuum-packed or Reduced Oxygen Packaging (ROP) seafood—and produces a deadly toxin if the temperature rises above 3°C (38°F).

Timestrip worked with the FDA to develop a specific Seafood Indicator. This label is calibrated to a strict 3°C threshold. If a shipment of fresh fish, clams, or oysters exceeds this temperature, the label provides a visual alert. This is a Critical Control Point (CCP) tool for HACCP (Hazard Analysis Critical Control Point) plans, ensuring that seafood entering the market is safe for consumption.

The Rise of Home Delivery and Meal Kits

The explosion of the direct-to-consumer food market (meal kits, grocery delivery) has moved the cold chain to the doorstep. Consumers receiving a box of raw meat or fish on their porch need assurance that it hasn't spoiled in the sun.

Timestrip indicators applied to the outer packaging or individual units provide this peace of mind. A clear indicator showing that the box remained chilled creates customer satisfaction and brand loyalty.

Catering and Logistics

Large-scale catering operations, such as those offering ‘food served on the move’ on airlines and trains, utilize Timestrip temperature indicators to manage the safety of thousands of meals, and avoid unnecessary disposal at the end of a shift. The use of Timestrip neo Multi in these environments allows for a sustainable, reusable solution that constantly monitors trolleys and storage units, ensuring that a sandwich served at 100 mph is as safe as one served in a restaurant.

6: Beyond the Cold Chain – Time Monitoring and Industrial Use

While temperature is a primary focus, the ‘Time’ in Timestrip indicators is equally vital. The company supplies indicators that monitor the passage of time, independent of temperature, or in conjunction with it (TTIs).

As above, time indicators operate in the same way as temperature indicators, and liquid-based and electronic versions are available. Timestrip liquid-based time indicators are activated by squeezing a blister, which releases a red dye into a porous membrane. The membrane is calibrated to control the flow rate of the dye. As time passes, the dye fills a window, marking intervals (e.g., 1 month, 3 months, 6 months).

Electronic indicators (Timestrip neo) again provides a practical alternative; its small form factor, lightness, accuracy and ease of use making it highly versatile. Timestrip neo Multi-X can be ordered in time-only configurations, accurately tracking time from minutes to months. This is ideal for filter replacement reminders, fume extraction, adhesives and chemicals procedures etc.

Applications in Filtration and Hygiene

- Water Filters: A common issue with home water jugs or fridge filters is remembering when to change them. A Timestrip attached to the filter housing provides a clear visual reminder: when the window is full, replace the filter.

- Healthcare Consumables: In hospitals, many items (like catheters or IV lines) have specific dwell times. A visual time indicator attached to the patient's chart or the device itself prevents overuse and reduces infection risk.

- Consumer Goods: Toothbrushes, mascara, and other personal care items have optimal lifespans. Integrating a small Timestrip label can remind consumers to replace old products, driving recurrent sales for manufacturers and ensuring hygiene for users.

Industrial Maintenance

In the industrial sector, preventative maintenance is key to reliability. Timestrip labels can be applied to machinery to track service intervals (e.g., "Service due in 3 months"). They are also used for monitoring the shelf life of chemicals, adhesives, and epoxies once opened. For example, a two-part epoxy might have a "pot life" of only 1 hour. A Timestrip 1-hour indicator prevents the use of cured, ineffective glue, saving rework costs in manufacturing.

7: The Strategic Value – Benefits and ROI

Adopting Timestrip technology is not just a safety measure; it is a strategic business decision with a tangible Return on Investment (ROI).

- Reduced Scrappage: The most immediate benefit is the reduction of waste. Without monitoring, a suspected temperature excursion often leads to the destruction of an entire shipment. With Timestrip smart labels in use, operators can see exactly how long the breach lasted. If the breach was within acceptable stability data limits (e.g., 20 minutes at 26°C for a product stable for 1 hour), the shipment can be saved. Using indicators at various points throughout a batch e.g. in a large vehicle, means that only affected parts of a consignment may have to be discarded.

- Audit Trail and Compliance: In regulated industries, documentation is key. Timestrip provides physical (and now digital) evidence of compliance with regulations like the FDA’s Food Safety Modernization Act (FSMA) or Good Distribution Practice (GDP) for pharmaceuticals.

- Brand Protection: A single recall or a case of food poisoning can destroy a brand's reputation. Timestrip acts as an insurance policy, preventing compromised product from ever reaching the consumer.

- Operational Efficiency: The visual nature of the indicators means that staff require minimal training. Decisions can be made instantly at the receiving dock without the need to download data or consult complex charts.

- Customer Satisfaction: For end-users, the visible presence of a quality monitor communicates that the brand cares about their safety.

8: Usage and Best Practices

To maximize the benefits of Timestrip indicators, proper usage is essential. The products are designed for ‘User-Centric’ operation.

Storage and Handling of Temperature Indicators

Most liquid Timestrip indicators are shipped in an inert state. This is a significant logistical advantage—they do not require cold shipping to prevent premature activation. They can be stored at standard room temperatures (typically around 22°C) until needed.

The Timestrip PLUS series generally does not require pre-conditioning, but users must ensure the indicator is activated in an environment above the threshold temperature (so the dye is liquid) and then immediately applied to the cooled product.

Activation of Timestrip indicators

Activation is tactile and simple. For the blister-style products, the user squeezes the activation button firmly. A coloured line appears to confirm the device is active. This built-in self-check mechanism ensures that the user knows the device is working before they walk away.

Reading the Result of Temperature Abuse

The Timestrip interface is designed for clarity.

- Arming Window: Shows the device is on.

- Breach Window: Remains white if conditions are fine; If a breach occurs, colour fills this window.

- Time Markers: In the Timestrip PLUS range, markers (e.g., 2 hrs, 4 hrs) allow the user to estimate the duration of the breach. This is critical for assessing the severity of the excursion.

9: Sustainability and the Environment

In the current global climate, sustainability is a prerequisite for business. Timestrip contributes to environmental goals in two distinct ways:

-

Waste Reduction

The primary environmental impact of Timestrip is the prevention of product waste. The carbon footprint of producing, processing, and shipping food or medicine is enormous. If that product is thrown away due to spoilage (or suspected spoilage), that carbon cost is doubled (production + disposal). By saving products that are actually safe (but might have been discarded due to doubt) and preventing the transport of already-spoiled goods, Timestrip significantly improves the efficiency of the supply chain.

-

Product Design

Compared with bulky, battery-powered traditional data loggers, Timestrip’s smart labels are extremely lightweight. This contributes to ‘lightweighting’ in logistics—reducing the fuel required for transport. Furthermore, the electronic Timestrip neo Multi promotes the circular economy by allowing reuse, reducing the volume of electronic waste (e-waste) associated with single-use loggers.

10: The Timestrip Ethos – Precision and Reach

Timestrip is a technology company dedicated to the integrity of supply chains. The company services customers around the world, both directly and through a robust network of specially trained distributors. This global reach ensures that whether a client is a multinational pharmaceutical giant or a local artisanal food producer, they have access to the same high standard of monitoring technology.

The company’s commitment to quality is codified by its rigorous adherence to international standards. Timestrip operates an IQC-approved certified manufacturing facility that conforms to ISO 13485:2016 and ISO 9001:2015. These are not just badges of honour but essential prerequisites for operating in the high-stakes worlds of medical devices and food safety. ISO 13485, in particular, demonstrates Timestrip’s capability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements—a critical factor when dealing with products like blood bags and vaccines.

Supporting a large stock range, the company boasts its own Research and Development (R&D) team. This internal capability allows Timestrip to go beyond off-the-shelf solutions, developing new products for bespoke applications. Whether it is a specific temperature threshold for a novel liquid-based indicator or a unique temperature / time design as a Timestrip neo indicator, Timestrip’s R&D engine drives continuous innovation.

Conclusion: The Future of Monitoring

In future, the demand for transparency in supply chains will only grow. Consumers are becoming more conscious of food safety; regulators are tightening controls on pharmaceuticals; and industries are seeking data-driven efficiency.

Timestrip sits at the intersection of these trends. By combining 20 years of manufacturing expertise with a continuous drive for innovation—from chemical engineering to digital connectivity—the company has established itself as an indispensable partner to global industry.

Whether it is the blue tint on a label saving a blood bag, the flashing LED on a vaccine shipment, or the red line on a water filter, Timestrip’s products are the silent guardians of quality. They provide the answers to the critical questions: Was it kept correctly? Has it been stored too long? Is it safe? In doing so, they deliver the ultimate commodity: peace of mind.