Temperature Monitoring Trends for 2025

At Timestrip, we don’t pretend to have predictive powers, but here are a few trends that are likely to be relevant to our time and temperature indicator markets in 2025.

Temperature sensitive packaging is a critical area of focus for many industries, especially pharmaceuticals, food, and biotechnology. By 2025, trends and innovations in packaging related to temperature control are anticipated to include those below.

Pharmaceutical Packaging, Labelling and Temperature Control

The pharmaceutical packaging sector is set to embrace smart technologies, eco-friendly materials, and enhanced safety features. Trends include the reduction of packaging layers to minimize waste while ensuring product safety and integrity.

- Advancements in Cold Chain Packaging

- Development of smart cold chain solutions, such as temperature monitoring devices integrated into packaging.

- Increased use of phase change materials (PCMs) and vacuum-insulated panels (VIPs) for improved thermal performance.

- GLP-1-Based Therapies

GLP-1 receptor agonists, initially developed for diabetes management, are being investigated for broader therapeutic applications. Real-world evidence suggests potential benefits in preventing or treating multiple chronic diseases, indicating a significant expansion in their use by 2025. Associated drugs for appetite suppression are finding enthusiastic take-up among health conscious individuals. These therapeutics are temperature sensitive, and Timestrip has developed several neo variants especially for monitoring semaglutide shipments.

- Eco-Friendly Materials

- Rise in biodegradable and recyclable cold chain packaging materials to meet sustainability goals.

- Adoption of reusable packaging systems to reduce waste. Removable temperature indicators can assist with packaging segregation.

- Compliance with Regulatory Standards

- Enhanced packaging designs to meet stringent global regulations (e.g., FDA, EU) for temperature-sensitive pharmaceutical transportation.

- Temperature Data Logging

- Increased use of embedded sensors and RFID technology to monitor and log temperature conditions during transportation. Tiemstrip’s TL520 mini data logger can deliver much of the benefits of a full data logger at much lower cost and with less complexity.

Food Packaging and Temperature Challenges

Sustainability remains a central focus, with trends pointing towards a reduction in material usage and pack sizes, as well as simpler packaging designs. Brands are also expected to adopt eco-friendly materials and enhance recyclability to meet consumer demand for environmentally responsible products.

- Active Packaging

- Growth in active cooling systems that use integrated gel packs or dry ice compartments.

- Use of time-temperature integrating indicators (TTIs) on packaging provide a signal if food has been exposed to unsafe temperatures. Timestrip’s TTI indicators track both time and temperature breaches.

- Reducing Food Waste

- Enhanced barrier technologies in packaging to maintain freshness and prevent spoilage caused by temperature fluctuations.

- Sustainable Insulation Materials

- Replacement of traditional polystyrene (EPS) with biodegradable and compostable insulators for food cold storage.

- Last-Mile Delivery Solutions

- Packaging designed to maintain temperature integrity during the crucial last-mile delivery, especially for grocery and meal delivery services. Simple temperature indicators such as the Timestrip neo can be read by end users as well as supply chain professionals.

Other Time Temperature Monitoring Innovations

- Smart Packaging Integration

- Use of QR codes, NFC tags, and other smart (‘intelligent’) technologies are increasingly used to track and ensure product safety across temperature-sensitive supply chains. Timestrip’s neo time and temperature indicators carry individual QR codes for product traceability and quality control procedures.

- Customized Solutions for Specific Needs

- Tailored solutions like modular packaging systems that adapt to different temperature ranges for diverse products. The increasing popularity of fresh and frozen pet food is reshaping packaging requirements in both online and offline channels.

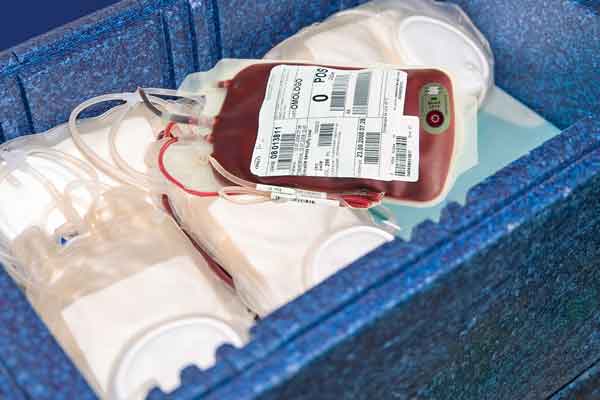

- Blood Supply Critical

- Last year saw concern in Brazil where 10% and 20% of blood stocks were discarded, due to conservation failures and contamination, according to Anvisa (National Health Surveillance Agency). While wastage of donated blood supplies is at a low level in the UK and USA, stock of key blood types dropped to dangerous levels at times during 2023, putting yet more focus on supplies management of blood bag temperature.

- Enhanced Predictive Analytics

- Software solutions paired with packaging to predict and mitigate risks of shipment temperature excursions. Some Timestrip products offer downloadable reports of temperature and time.

- Logistical Adaptations

- Partnerships with logistics providers to streamline temperature-controlled shipping practices using advanced packaging.

- Aircraft Supply Chain

- The aircraft supply chain is anticipated to undergo significant changes, with a focus on sustainability and efficiency. Companies are expected to adopt smaller, more flexible packaging solutions that minimize wasted space, aligning with broader industry trends towards sustainability. Aircraft deliveries are forecasted to rise again after several year downturn; temperature indicators from Timestrip can help monitor cold chain shipment conditions and food served on the move.

By focusing on eco-friendliness, technological integration, and regulatory compliance, industries are addressing the dual challenge of maintaining product quality and minimizing environmental impact.