Reduced Oxygen Packaging

with Ferme Marine de Mahebourg

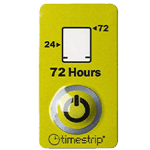

Seafood cold chain logistics from packaging to distribution with Timestrip Seafood.

Contact us for your solution

“Timestrip TTIs not only allowed for access to the US domestic seafood market, but also led to more sales.”

Tommy Sawmy, MD, Ferme Marine de Mahebourg

Company Profile

The Ferme Marine de Mahebourg is a fish farming company based in Mauritius and has been a user of Timestrip since 2015. The company produces three types of fish — Sea Bass, Red Drum and Dusky Kob — and has just over 100 employees.

It produces over 1,000 tonnes of fish annually, with production for 2017 forecasted at 1,500 tonnes and a target for 2020 of 3,000 tonnes. 95% of its production is exported, with the remainder going to mainly high-end hotels on the island. Its main markets are the US and the EU, which account for 50% and 40% of its exports respectively.

It produces over 1,000 tonnes of fish annually, with production for 2017 forecasted at 1,500 tonnes and a target for 2020 of 3,000 tonnes. 95% of its production is exported, with the remainder going to mainly high-end hotels on the island. Its main markets are the US and the EU, which account for 50% and 40% of its exports respectively.

Monitoring of seafood packaging & shipments

Timestrip Temperature Solutions

The company approached Timestrip to manage two issues: Firstly, the FDA-approved oxygen permeable bags they had been using up until that point had an adverse visual effect on its products. Oxidation made the veins of the product turn brown and although in no way did this impact on quality, aesthetically it no longer looked fresh. In fact, the company received quite negative feedback from its customers about this. One was: “Why are you sending us old (looking) fish?”

Secondly, as with the oxygen permeable bags, the solution had to comply with FDA regulations. This was absolutely essential for access to the US market. Timestrip Seafood 3°C TTI labels could easily handle the first problem, as they are specially designed for vacuum packaged products. This low oxygen environment keeps products looking fresh until receipt by the end-user.

Secondly, as with the oxygen permeable bags, the solution had to comply with FDA regulations. This was absolutely essential for access to the US market. Timestrip Seafood 3°C TTI labels could easily handle the first problem, as they are specially designed for vacuum packaged products. This low oxygen environment keeps products looking fresh until receipt by the end-user.

Benefits of Timestrip Food in the seafood industry

Moreover, because there is a high risk of Clostridium botulinum toxin growth with vacuum packaging at temperatures above 4-5°C for over 4 hours, they also work as a C. bot prevention tool. Also, Timestrip Seafood 3°C TTI labels were designed with the FDA guidance in mind, a crucial requirement for the company given that half of its exports are for the US market.

Apart from access to the US market, a related benefit of using an FDA compliance cold chain management tool is that the company is placed on a so-called “Green List”. This means that its products are not detained at receiving US airports and are only checked for temperature. This benefit is 100% correlated to the Timestrip seafood indicator being in compliance with FDA guidance and means the company’s US customers get to process their received products without any delays. Also, their use of Timestrip temperature indicators led to more business for the company.

Apart from access to the US market, a related benefit of using an FDA compliance cold chain management tool is that the company is placed on a so-called “Green List”. This means that its products are not detained at receiving US airports and are only checked for temperature. This benefit is 100% correlated to the Timestrip seafood indicator being in compliance with FDA guidance and means the company’s US customers get to process their received products without any delays. Also, their use of Timestrip temperature indicators led to more business for the company.