Safeguarding Products in Winter: The Value of Temperature Indicators

When winter sets in, cold imposes risks on a wide range of sensitive goods, from paints and adhesives to flowers, fruits and vegetables, and of course medical products such as vaccines.

Many of these goods are living tissues or chemistries that degrade if exposed to unsafe temperatures. Temperature indicators offer a simple but powerful line of defence, giving early warning, supporting quality control and helping avoid loss.

Products at Risk in the Cold

Paints and adhesives

What goes wrong with industrial materials such as paints, adhesives and fibre glass precursors when exposed to low temperatures?

-

Freezing or crystallization in water-based systems

Water in adhesives or paints can freeze, causing the internal structure to be damaged (ice crystals forming, separation of components). Once frozen/damaged, they may no longer perform properly.

-

Irreversible chemical or physical changes

Cold can slow or stop curing; certain polymers become brittle; water-based dispersions may coagulate irreversibly.

-

Substrate and adhesion issues

Cold surfaces can cause adhesion problems; moisture or frost on bonding surfaces acts like a separating layer and prevents proper bonding.

Due to these risks, manufacturers often specify storage temperature ranges such as 5-25°C for many adhesives, and warn against storage below certain thresholds.

Flowers (cut flowers, potted plants, bulbs)

-

Freezing damage

If flower cells freeze, ice crystals can rupture cell walls, leading to wilted, mushy or discoloured petals or stems. Even brief exposure below 0°C (32°F) can cause damage.

-

Wilting and accelerated ageing

Flowers have high respiration rates, which increase with temperature fluctuations. Cold slows these processes, but abrupt temperature drops followed by rises can stress tissues, reduce vase life, or promote fungal growth (e.g. Botrytis).

-

Chilling injury

Some flowers (especially tropical or subtropical species) are damaged by exposure to relatively mild cold (just above freezing). Symptoms may not show immediately but will be revealed after the flowers are returned to warmer conditions.

Fruits and vegetables

-

Freezing vs chilling damage

- Freezing (temperatures below about 0°C usually causes immediate and visible damage: water in the plant cells turns to ice, cell rupture, surface cells collapse, sogginess, etc.

- Chilling injury refers to damage that happens in some produce when stored at moderately low temperatures (above freezing, but below what they prefer). Symptoms may appear only when the produce is moved to warmer conditions.

-

Additional risks

- Moisture loss (wilting, shrivelling) increases at low relative humidity, and low temperatures sometimes paired with low moisture accelerate decay.

- Low temperature can also increase susceptibility to rot, particularly when damage from frost or chilling weakens tissue.

Timestrip temperature indicators in Winter

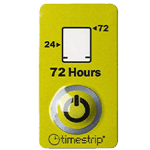

Use of electronic or liquid-based temperature indicators can help to prevent damage by providing clear, irreversible alerts when expected temperatures are breached. These low cost, easy to use devices provide the following benefits:

-

Early warning in the supply chain

As goods travel from factory → warehouse → truck → final destination, temperature changes can occur. indicators stuck on or inside packaging can show that temperature risk has occurred at any stage. this allows corrective action e.g. rejecting goods, changing conditions) before use.

-

Quality assurance and liability protection

If a shipment arrives and the temperature indicator shows exposure to damaging cold, the receiver can inspect, test, or reject product rather than unknowingly use compromised material. this helps avoid failures in application, which could be costlier, and provides evidence for claims against shippers.

-

Optimising costs and reducing wastage

Paints or adhesives damaged by cold may have to be thrown out or require rework. indicators reduce these losses by flagging potential damage before damage is committed (e.g. before mixing or applying product).

Example Scenarios of Winter Temperature Monitoring

-

Flowers shipped overnight in winter

Roses may be sent from a grower to a retailer in sub-zero outside temperatures. If the transport vehicle isn’t well insulated, the internal temperature might drop below freezing. A temperature indicator threshold 0°C stuck inside the flower crate will show the exposure. The retailer notices this, rejects or treats the roses accordingly (e.g. moves them to a warmer cold room), so they avoid selling wilted or frost‐damaged flowers.

-

Vegetables stored in unheated warehouse

Root vegetables or leafy greens may be stored in a warehouse during a cold snap. Outside temperatures may cause the building interior, or particular corners, to drop below the safe range. If indicators are placed per batch or per pallet, those pallets that get too cold (or have repeated dips) can be identified, warmed or used up first, reducing spoilage.

-

Mixed shipments

Suppose a shipment contains both hardy vegetables (like carrots) and chill-sensitive ones (like cucumbers). The same critical temperature may be safe for carrots but damaging for cucumbers. Using multiple indicators (or indicators set for the more sensitive item) allows the cold-sensitive produce to be flagged and protected.

Case Study: Berries — Shelf Life Losses Due to Temperature Variability

In a paper entitled ‘Reducing Food Losses by Intelligent Food Logistics’ (ref.1), the authors describe an analysis of berry supply chains, where temperature sensors were used at various points, tracking pre‐cooling, transport, etc. They found that large variability in temperatures along the chain (especially during long transports and for pallets in different positions) resulted in 57% of berries arriving at packing houses with insufficient remaining shelf life for the longest transport routes. Losses due to spoilage were much higher.

Also, the authors concluded that pallets inside a container of strawberries shipped across the continental USA will have up to 5°C temperature differential depending on where they are placed inside the container, causing a notable difference in their quality and shelf life. Hence, a temperature controlled container's set point is an extremely poor approximation of the actual product temperature. A better quality monitoring system is needed using higher resolution than the container level. Timestrip indicators are small and light and are ideal for placement within batches of product, thus giving more localised monitoring.

Safeguarding Products for Winter Transport Conclusion

Temperature indicators are an invaluable tool in protecting a wide range of temperature-sensitive goods through winter. By providing visual, irreversible warnings of temperature breaches, they help ensure quality, reduce waste, protect reputation and enable more confident decision-making in cold chain logistics.

Ref. 1: Royal Society Publishing