Train Catering

with Amtrak

Monitor the temperature of food and beverage catering on trains.

Contact us for your solution

“This has saved the Los Angeles hub over $337,000 in one year. Without Timestrip, this would not have been possible because the FDA previously would not allow them to keep the refrigerated food items onboard.”

Timothy Corbett - Manager of Special Projects at Amtrak

Company Profile

Amtrak is the US nationalized rail transport carrier. It operates 300 trains a day over 21,300 miles of track in 46 US states, serving over 500 destinations. During 2016, the company transported some 31m passengers (1) and forecasts for 2017 predict revenues for the year of over (2) and an operating loss of $255m(3).

Monitoring temperature of train catering

Timestrip Temperature Solutions

The provision of a high-quality Food and Beverage (F&B) service is especially important on the company’s long-distance routes as although a loss leader, it not only enhances their customers’ travelling experience, it is also a key factor that they use in deciding whether to travel by rail and thus supports ticket sales.

According to Amtrak’s January 2017 financial report, F&B revenues are forecasted to be approximately $133m(4) for the year, covering just over half of their costs (5). Addressing this situation is an urgent priority for the company as the Fixing America’s Surface Transportation (FAST) Act, which was passed in 2015, directs it to develop a plan to eliminate the operating loss for onboard F&B services. Moreover, from 2021 the act bars the use of federal funds to cover any such loss.

According to Amtrak’s January 2017 financial report, F&B revenues are forecasted to be approximately $133m(4) for the year, covering just over half of their costs (5). Addressing this situation is an urgent priority for the company as the Fixing America’s Surface Transportation (FAST) Act, which was passed in 2015, directs it to develop a plan to eliminate the operating loss for onboard F&B services. Moreover, from 2021 the act bars the use of federal funds to cover any such loss.

( 1 ) Amtrak national facts

( 2 ) Amtrak Monthly Performance Report For January 2017 page A 1-3 forecast column

( 3 ) Ibid.

( 4 ) Ibid.

( 5 ) Ibid., A 2-1: F&B Cost Recovery Ratio

( 2 ) Amtrak Monthly Performance Report For January 2017 page A 1-3 forecast column

( 3 ) Ibid.

( 4 ) Ibid.

( 5 ) Ibid., A 2-1: F&B Cost Recovery Ratio

Benefits of Timestrip Food Temp in catering

Before Amtrak started using Timestrip TTIs, the company’s procedure had been to remove all food items from the trains when they pulled into the station for the evening. This was due to an FDA concern that while the trains were serviced in the evening, the power could be shut off and food would spoil presenting a danger to the public.

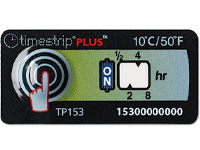

Amtrak contacted Timestrip because it had the best prices on an 8°C product and were inert prior to activation. Tim says that the company in fact only needed a 4-hour 8°C TTI, so Timestrip created this product specifically with them in mind, which is now the TP-349 Food 8°C/46°F.

An unexpected outcome was that by creating a smaller time window, Timestrip were able to help the company reduce costs further. The procedure Amtrak now operates involves the last F&B crew placing numerous TP-349 labels on the tops of yogurt containers (which have an aluminium cover) before leaving the train in the evening. The following day, the first crew must check to make sure that none of the yogurts in the various refrigeration units have had a breach of temperature.

Because of the successful use of Timestrip Food Temp TP-349 TTI on Amtrak’s West Coast line, further use of the product will be rolled out elsewhere on the national network.

Amtrak contacted Timestrip because it had the best prices on an 8°C product and were inert prior to activation. Tim says that the company in fact only needed a 4-hour 8°C TTI, so Timestrip created this product specifically with them in mind, which is now the TP-349 Food 8°C/46°F.

An unexpected outcome was that by creating a smaller time window, Timestrip were able to help the company reduce costs further. The procedure Amtrak now operates involves the last F&B crew placing numerous TP-349 labels on the tops of yogurt containers (which have an aluminium cover) before leaving the train in the evening. The following day, the first crew must check to make sure that none of the yogurts in the various refrigeration units have had a breach of temperature.

Because of the successful use of Timestrip Food Temp TP-349 TTI on Amtrak’s West Coast line, further use of the product will be rolled out elsewhere on the national network.