Food Monitoring – Novel Applications

Many people are aware that Timestrip indicators can be used for monitoring temperatures in the food cold chain. Travelling with the products, the indicator reveals breaches in temperature and in some cases the cumulative duration of the breach.

However, there is a surprising level of variety, even novelty, about the applications that utilise this technology. Here are just a few examples.

Train catering temperature monitoring

Before Amtrak started using Timestrip food temperature indicators to monitor train catering temperature, the company’s procedure had been to remove all food items from the trains when they pulled into the station for the evening.

The procedure Amtrak now operates involves the last crew placing numerous TP-349 labels on the tops of food containers before leaving the train in the evening. The food can be left in the train since the following day, the first crew can easily check whether any of the refrigeration units have had a breach of temperature, and take appropriate action. A significant time and cost saving for Amtrak.

“This has saved the Los Angeles hub over $337,000 in one year” stated a senior Amtrak manager.

Oyster shipment monitoring

Customer consignments are shipped in specially manufactured cardboard carriers with frozen gel pack inserts to help maintain core product temperature below 50°F during transit.

However, a delay in transit or repeat exposure to excessive ambient air temperatures when truck doors are opened can affect the integrity of the cold chain. Regulations require Island Creek to prove they have maintained temperature controls across the supply chain.

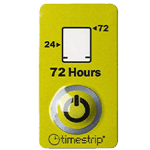

Island Creek chose to use the Timestrip PLUS, 10ºC TTI to provide active oyster temperature monitoring throughout the cold chain. The Timestrip PLUS is activated by finger pressure and attached to the base of the box in between the frozen gel packs and prior to the seafood being packed and the box sealed for shipment.

The temperature indicator has an irreversible notification of temperature breach above 50°F, and the length of any cumulative breaches measured in 2 and 4 hour time frames.

Once delivered, customers have a simple mechanism to visually alert them to a temperature breach and if so, how long it lasted, which in turn allows the customer service teams to advise as to whether they should discard the product or not.