Every Timestrip® PLUS product is calibrated to a temperature of 2ºC above its stated threshold temperature. For example, Timestrip® PLUS 12ºC is calibrated to a temperature of 14ºC. When the product breaches its threshold temperature and is held at a constant temperature(i.e. isotherm) of 14ºC, it will reach the 1 Hour print mark within 1 Hr (+/- 15% in time).

The maximum run-time varies between hours to days dependent on the product and its application. Note that the run-time is only referring to the time above its breach temperature. Timestrip® PLUS can remain active and vigilant for long periods of time (up to a year after activated) if the run out window has not completely filled in.

The activation window gives confidence that the product is armed. The breach/run-out window is separate so that it clearly indicates a breach of the temperature threshold and the cumulative elapsed time of the breach.

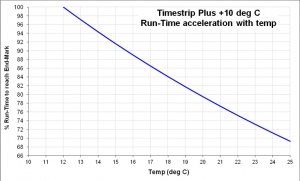

Due to the nature of liquids, higher temperatures reduce the viscosity of the liquid dye in Timestrip® PLUS. The correlated result is faster/shorter run-times (the progressing blue dye will reach each printed time-mark sooner than intended). So, if an 8ºC/46ºF indicator is exposed to 25ºC/77ºF for a consistent period then the blue dye will progress more quickly through the membrane than if it was exposed to 10ºC/50ºF for a consistent period. This graph shows the run-time acceleration of a 10ºC/50ºF Timestrip® PLUS at different elevated temperatures.nnThe y-axis represents the actual run-time of the liquid dye at different temperatures, and is expressed as a percentage of the specified run-out time at an isotherm of 12ºC/54ºF. So, at an isothermal temperature of 12ºC, the liquid dye will reach each time-marker (1, 2, 4, 8, hours etc) within these times +/-15% in time. However, if for example the product is exposed to an isotherm of 21ºC/70ºF the dye will reach each time marker within only 77% of the intended run-time. In other words, it will reach the;n

- 1 hour time-marker within approximately 46 minutes (77% of 1 hour)

- 2 hour time-marker within approximately 1.32 hours and so on.

At a less extreme temperature elevation, say 15ºC/59ºF the blue dye will reach each time-marker at 91% of the intended time.

Timestrip also offers a ‘tti thermometer’ in the form of the Timestrip VST TTI that is designed to integrate time and temperature.

Timestrip® PLUS are polymeric multi-layer indicators. They are based on spontaneous lateral wetting by a blue liquid inside a porous substrate and not a chemical reaction. Each production batch (7000 - 8000 products) undergoes strict quality control tests to validate its time accuracy. This is conducted via a computer vision software (TSCV) which analyses scanned photos of seven randomly-selected products from each batch (roughly 0.1% of the population). The photos are taken at different elapsed times and the tested products are placed at their designated temperature through the entire test period. The software automatically analyses the lateral progress and the elapsed time of each product tested and the data is presented numerically and graphically in a specific file which is labelled by batch. This data is translated into a final release report which is attached to the outgoing product batches.

The Accepted Failure Rate is based on ANSI/ASQC Z1.4 (formally MIL-STD-105E) Level II Normal Inspection. Packs are over shipped by 2-3 units per 100 to cover this AQL.nnCentral to this process are tests against defined specifications for; how quickly the dye progresses through the membrane, environment sensitivity (high heat and vacuum tests to check resilience to harsh conditions during shipping) and also the accuracy of the threshold melting point. A full pack of release reports is provided with each shipment. Further details are available on request.

Yes. Please contact us for the MSDS for further information. We only use food-grade oils and non-toxic colourants in our formulation. In the unlikely event that the liquid leaks from the indicator and comes into contact with skin, simply wash with soap and water. If the liquid comes into contact with eyes, rinse immediately with plenty of water and seek medical advice.

Because we like our customers! You can use these free products for testing, training, validation, or just to save money. In the unlikely case any got damaged along the way or someone just wanted to try one, there is no need to get in touch, although we're always happy to hear from our customers. Personally, we think that all companies should give stuff away for free!

Timestrip® PLUS can only show ascending temperature excursions. We have other products that do this type of descending temperature indication.

Yes. Orientation has no impact on the way it works.